Crane overload protection

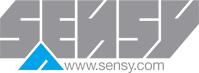

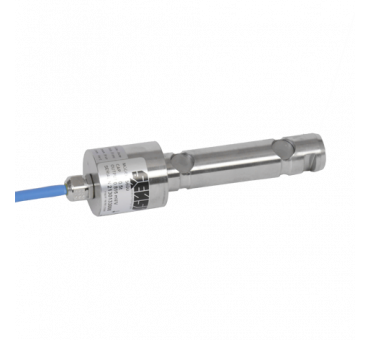

Load pin, wire rope load cells,

Since 1986, SENSY has specialised in manufacturing load-limitation systems for cranes, gantries (EOT cranes), lifting tackles, port gantry cranes and other lifting/hoisting equipment.

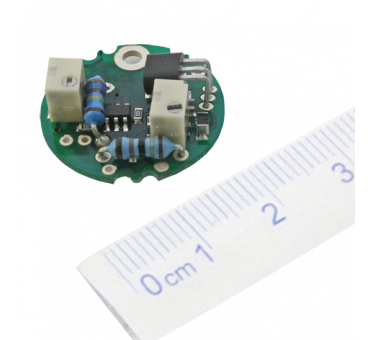

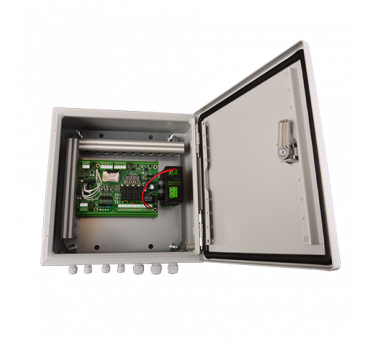

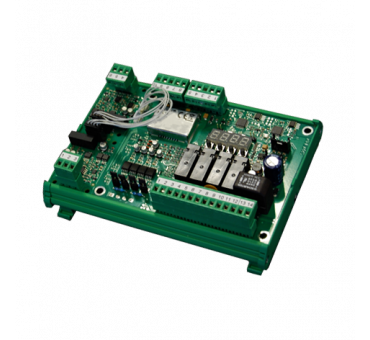

These systems comprise a force transducer that generates a signal proportional to the load being lifted and an electronic device.

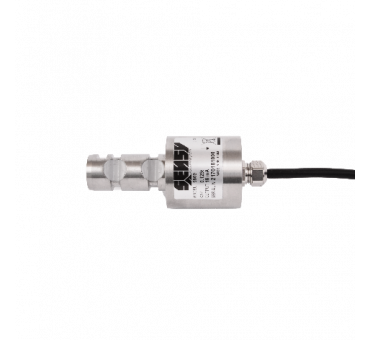

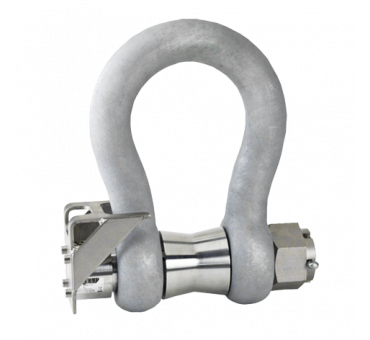

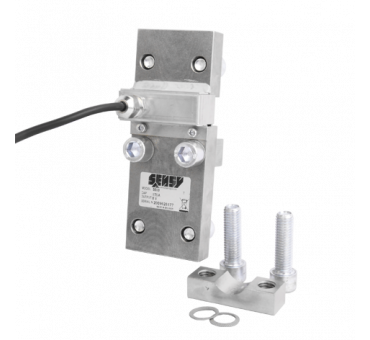

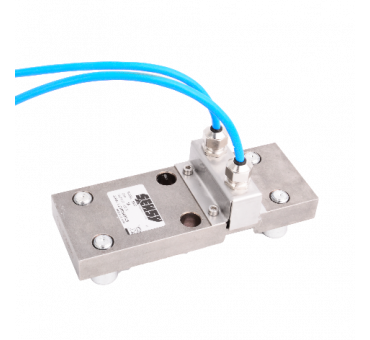

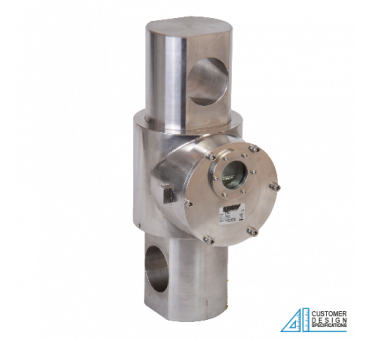

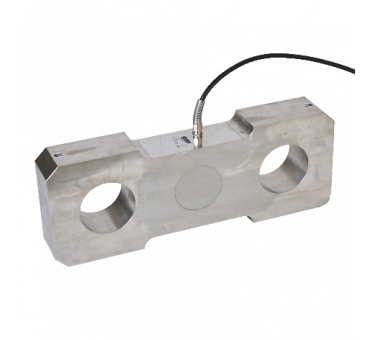

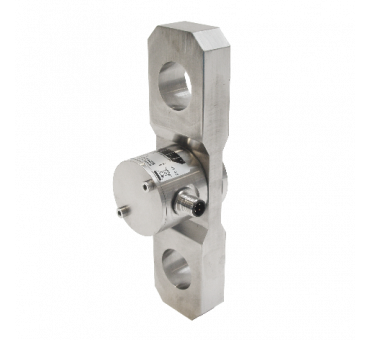

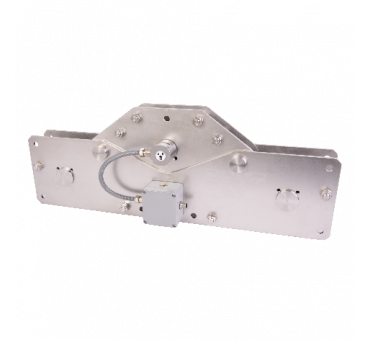

This sensor can be a load cell to be mounted on the wire rope (economical solution), a load pin (standard or custom-made), a load-measuring wedge socket, an instrumented load shackle or any other compression or tension model able to offer you the best solution.

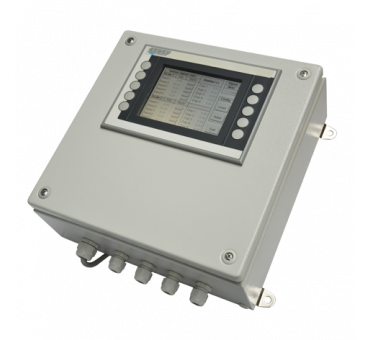

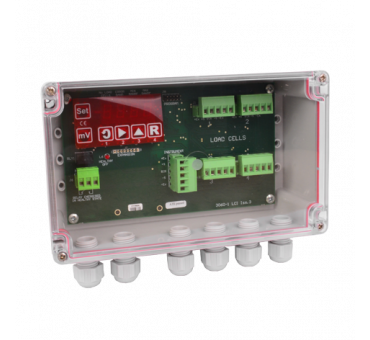

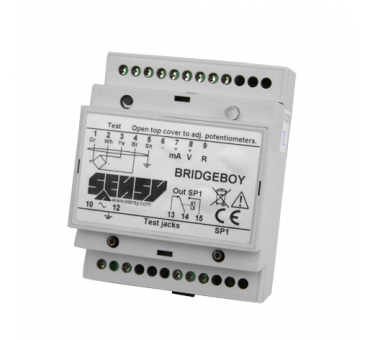

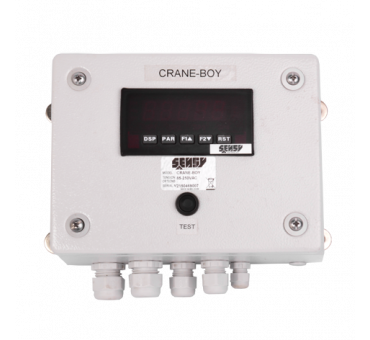

This transducer must be connected to load-limitation electronics which allow you to interrupt the rising of the load in case of overload. These electronics can also detect a slack cable or manage a pre-alarm. They are available in an economical version (BRIDGE-BOY) to provide, in combination with a wire rope load cell, a solution for small capacity lifts. A more elaborate version (CRANE-BOY) provides easier calibration, courtesy of its display for more complex systems.

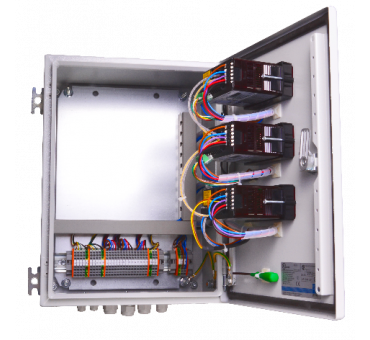

In recent years, the trend has been to move towards more elaborate security systems complying with standards EN ISO 13849 (PL safety class) and EN 62508 (SIL safety class). SENSY helps you by offering a range of redundant sensors in this field and providing you with the necessary calculations, as well as an appropriate load limiter.

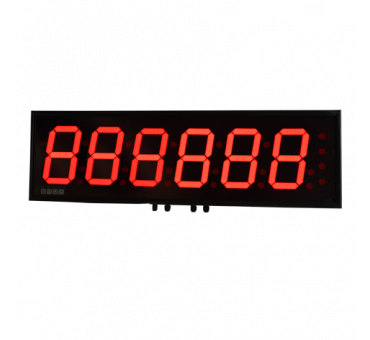

In addition, SENSY offers a complete range of large displays (from 57 to 400 mm high).

SENSY has also developed electronics system called COACH which can be used as a black box to control the use of the crane and optimise its maintenance (calculation of the Safe Working Period (SWP).

Finally, whether from the point of view of the sensor or the electronics, SENSY can offer you a tailor-made solution perfectly adapted to your application.