These load cells can be certified as explosion-protected equipment with different types of protection (Ex i, Ex n or Ex d) for use in different explosive zones:

Gas zones

- Zone 0: presence of an explosive mixture either continuously, frequently or for long periods;

- Zone 1: occasional presence of an explosive mixture during normal operations;

- Zone 2: presence of an explosive mixture unlikely to occur during normal operations, but if it does will only persist for a short period.

Dust zones

- Zone 20: presence of an explosive mixture either continuously, frequently or for long periods;

- Zone 21: occasional presence of an explosive mixture during normal operations;

- Zone 22: presence of an explosive mixture unlikely to occur during normal operations, but if it does will only persist for only a period.

SENSY provides a wide range of Zener barriers and galvanic isolators in order to comply with the intrinsic safety rules.

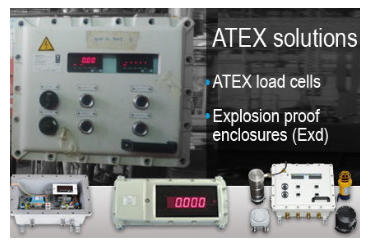

We also offer a complete range of ‘Ex d’ certified explosion proof enclosures for electronics that are used in hazardous atmospheres. These enclosures are designed to contain amplifiers, displays, load limiters and Zener barriers or galvanic isolators, etc.

The transducers, but more often, the explosion-proof enclosures are tailor-made to better meet the required specifications.

Since our first ATEX certification in 1997, we have developed a great deal of experience in this field. More recently, we have been awarded two new intrinsic safety certifications: CSA (for the USA and Canada) and IECEx (worldwide).

Not only do these certifications impose additional technical constraints, but they also enforce compliance with a specific quality assurance system, thereby guaranteeing quality. And, as expected, our quality system is also EN 13980 certified.

Examples of applications include:

- chemical and petrochemical industries

- oil exploration and exploitation

- industries and laboratories active in the field of hydrocarbons

- cereals storage

- etc…