That is why we regularly respond to specific requests, such as:

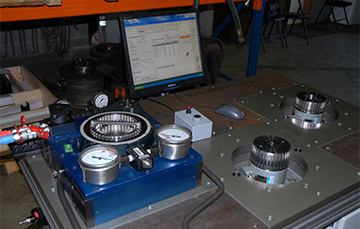

More than just a manufacturer of measurement components, we are also a solutions provider. So we often work with integrators to develop test benches. The example below illustrates one of our most recent projects:

Problem :

At the request of a company specialising in the manufacture of hydraulic equipment, SENSY participated in the study and realisation of a test bench for the calibration of torque wrenches and dynamometric keys for an aircraft engine manufacturer.

Specification :

- Torques to be measured ranged from 200 to 40,000 Nm.

- The required precision was 0.1%.

Solution :

As part of this project, SENSY manufactured three torquemeters and also designed the software for a measurement management programme according to the customer’s specifications.

Torque transducer design:

- Capacities:

- 2,000 Nm

- 10,000 Nm

- 40,000 Nm

- Accuracy: ± 0.1

Calibration at the French National Laboratory for Metrology and Testing (LNE) in Paris. Supply of the necessary equipment for the mechanical interface between the torquemeters and the calibration machine. - Signal output: USB

- Dimensions: tailor-made with grooves according to DIN 5480-1 standard (120 mm).

Data acquisition and processing software design with the following main functions:

- Test data encoding (operator, customer, references and accepted measurement tolerance, etc.)

- Torque measurement with display

- Certificate printing

- Audible alarm when the transducer capacity is reached

- Data recording in a Microsoft Excel® file.

This application example shows how SENSY is able to meet the specific needs of the market in the torque measurement field and to work with integrators to provide know-how in complementary disciplines.

Even though we are able to respond to such specific and one-off demands, it should not be forgotten that SENSY also offers a range of standard reaction and rotating torque transducers with capacities ranging from 2 to 10,000 Nm.